HCT Well Rehabilitation Research

- Jul 1, 2022

- 2 min read

June, 2022

Keywords: Acid, Descaling Volume, Descaling Rate / Corrosion – Alloy

How do we descale effectively while minimizing corrosion on soft alloys?

416 Stainless Steel (416) is a soft alloy. It is commonly used in water wells as the shaft that turns the bowls.

416 is commonly used because it is easier to mill than other stainless alloys.

416 is very soluble in strong acids.

Can environmentally safe inhibitors be applied to minimize acids attack on the 416 alloy, in that we might be able to descale wells with the column pipe, bowls and shaft left in place, without removing the pump, "insitu - pump in place"?

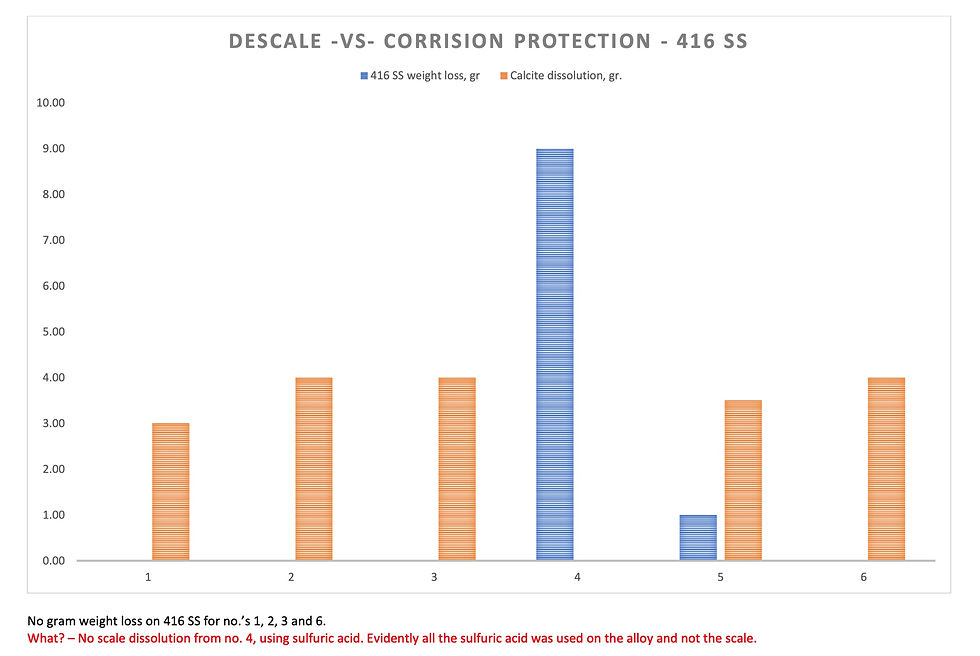

Products Evaluated

HCT’s Well-Klean© Pre-blend with a supplemental inhibitor we’ll call T

A commonly used weak acid

HCT’s Well-Klean© Pre-blend with a supplemental inhibitor we’ll call A

93% Sulfuric Acid

HCT’s Well-Klean© Pre-blend

HCT’s Well-Klean© Pre-blend with a weak acid

Blending

200 ml beaker 5% main descaler plus tap water for items 1, 3 and 6. 5% main descaler plus supplemental inhibitor/catalyst, plus tap water for items 2, 4 and 5.

Exposure

18 hours (no more visible reactions occurring)

Substrates

Single Calcite Crystal (about 1 inch squarer) 416 Stainless Steel Disc cut from a 2-inch column shaft pipe – approx. 1/8th in thickness.

Summation

One certainly does not want to put sulfuric acid downhole for descaling if the column shaft is 416 SS and is left in the hole, due to sulfuric acids damage to 416 SS, and not dissolving scale. Sulfuric dissolved no scale. Is this the characteristic of sulfuric when mild steel casing is involved? Does the acid attack the iron metal more aggressively than the scale, like it did with the 416 SS?

Item 6 produced no corrosion and the most amount of scale removal.

Each product, other than products 4 and 5, provided substantial corrosion suppression to perhaps allow for descaling a well with 416 column shafts in place.

HCT would recommend products 2, 3 and 6 as acceptable and equals for “Insitu” well descaling.

HCT would recommend products 6 for agricultural corrosion inhibition like for use in pivots.

Items 1, 2, 3 and 6 would be experienced to provide flash rust protection as well. The rusting of the alloy after it is taken out of use and exposed to the atmosphere would be potentially mitigated.

Our previous experiment with Well-Klean© Pre-blend against sea shells, then left to soak for a week.

Well-Klean© - Top Sulfuric acid - Bottom

There are a lot of things people don't realize about water wells and the industry itself has not been aware of or accustomed to. In turn, things have been done to wells believed to be beneficial and rewarding, and yet technically, in most cases, short term, temporary relief, and followed by bigger trouble to come, over a shorter range of time than previously, and at a higher cost time over time with diminishing recovery of water production. This is called “Declining Specific Capacity” and it’s the reason HCT got into the business in wells. We, HCT, believed we could reverse the trend of wells declining in production capacity between cleanings, and we did.

Inquiries will be responded to immediately during business hours (7am - 5pm MST)

email: info@hctllc.com

Phone: (888) 788-5807

Comments