Case Study: Chemically Remediating, Flushing Greens

- Nov 23, 2021

- 12 min read

Updated: Dec 2, 2021

September 27, 2021

Green #3 Lab ID: 21080020

The Legends’ greens had been evaluated for their chemical and physical conditions in the Fall, 2020 by Robert Oppold of ISTRC and Dr. York of Tournament Turf Laboratories (hereafter: “TTL”). Water quality was reported as poor by the experts. The soil testing incorporated the improved methods using the York-Oppold Legacy Testing Package through Tournament Turf Laboratories, and exhibited that Fe, Ca, and other metals (Al) were extremely high, significantly more then conventional exchangeable methods (AA, DTPA and Mehlich III) portrayed. The greens were found to have extreme hardpan midway through the soil profiles.

The physical properties testing through ISTRC confirmed poor infiltration/percolation through the root zone profiles, low air porosity, and high water retention properties (water porosity and water holding). The greens were excellent candidates for treating the water and soils with HCT’s Curative and BC products. Rather than handling Curative and BC in their concentrated condition, HCT’s pHix product was chosen. pHix is Curative and BC blended in a solution that is easier, more user friendly, and compatible with most topically applied products.

At ISTRC and TTL recommendations, a commercially available HCl product for comparison purposes of the urea buffered acid products available in the marketplace (hereafter: “Product B” unless stated otherwise).

I. RESEARCH QUERIES

No. 1. How much product can turfgrass tolerate? This is a practical question because of the hypothesis that the rate directly impacts the amount of time required to remediate soil chemistry issues below the surface. In addition, the rate has a direct impact on the amount of nutrients that can be liberated within a given time frame.

The more nutrients that can be liberated and sequestered within a given time frame should equate to more rapid removal of those liberated and sequestered nutrients through plant uptake and leaching.

No. 2. Is it possible to change soil chemistry and soil physics within a 12 day testing window that was reduced from the original 30 days? Given the limited 12 day testing period available, the expectation was that there should be a measurable change in chemistry but changes to the physical properties were predicted to be “minimal, at best”.

No. 3. Would there be a measurable difference between pHix and the urea buffered HCl product? pHix is a combination of the Curative product – HCl based, and BC which consists of Hydrogen Peroxide, both contain an ammonium acetate and other proprietary ingredients. [NOTE: Product B was chosen because HCl is a stronger acid than sulfuric acid.]

II. CONCLUSIONS

Conclusion #1. The turf was able to tolerate solutions of 500 ppm of the pHix and the Product B. No yellowing or adverse reactions were observed. Our conclusion, that the turf could tolerate substantially higher concentrations except that Product B caused a flush of leaf tissue growth and drops of raw product burned the turf. Likewise, Product B, the grass became puffy and soft. We attribute the flush of growth to the urea. The Product B was rated as 17-0-0. The flush of growth limits its use to remediate soils in that no fertilizer was applied during the 12 day testing period. A similar flush of growth was not observed with the pHix.

Conclusion #2. There were measurable changes in soil chemistry with both the pHix and Product B. There were also measurable improvements in the physical properties particularly in the 8-to-12-inch strata (3rd tier), which was contrary to expectations.

These tests were the first time we were able to directly attribute high bulk densities to contaminants in a sand-based root zone. In the 3rd tiers, the pHix and Product B lowered bulk density and increased both air porosity and water infiltration/percolation.

Conclusion #3. The pHix is a solution consisting of 20% active ingredients - Curative (HCL) and BC (peroxide and acetic acid) - and 80% water. Product B is approximately 60% buffered HCl and 40% water. There were measurable differences between the two products. Product B, for instance, produced a larger change in water infiltration/percolation and a larger change in the porosity properties in the 3rd tier; however, the pHix was able to produce a substantially lower bulk density with almost one-third less active product.

Both products were effective with the carbonates and bicarbonates and both mobilized Fe. The pHix’s lower bulk density, however, indicates that it was more effective in dissolving hard crystalline structures and flushing the residual.

Conclusion #4. Physical and chemical changes occurred over a short period of time. The flush of growth associated with the Product B was attributed to the urea N. There was insufficient time to measure the ability of the grass to uptake the liberated nutrients thereby reducing fertilizer costs. Additionally, there was insufficient time to improve the physical properties of the top 4 inches. There was a black layer that extended from the surface to about the 5th inch.

The layer did not have the rotten egg smell that is typically associated with hydrogen sulfide produced black layer. The blackened root zone mix was more likely caused by an anaerobic induced reduction reaction involving Fe & Mn. On the 12th day, it was observed that the black soil in the pHix 500 ppm test plot appeared to have lightened.

The testing indicated that the pHix moved more Fe & Mn than Product B; however, the more likely explanation for the lightening of the soil was the impact of the peroxide and O2 or a combination of the acid/peroxide/HAA of the pHix.

III. TESTING PROCEDURES

Test plots for the pHix and Product B were marked with paint. The size of each plot was 3 ft. x 5 ft. There were three sets of two plots: 50 ppm, 250 ppm, and 500 ppm. The picture on Page 3 is an accurate depiction of the set up. In the photo, the nearest squares are the 50 ppm for pHix and Product B. The next two squares are the 250 ppm applications. The furthest two squares are the 500 ppm applications.

The parts per million were calculated based on each product as it is commercially available. As a consequence, the Product B would have had slightly more than 25 ppm, 125 ppm, and 250 ppm of buffered HCl in solution based on its approximate 60% of active product in the commercially available solution. In contrast, the active ingredients of the pHix would have been approximately 8 ppm, 42 ppm, and 83 ppm. [NOTE: The remainder of this report will refer to the parts per million based on the products as commercially available irrespective of their percentage of active ingredients unless specifically stated otherwise.]

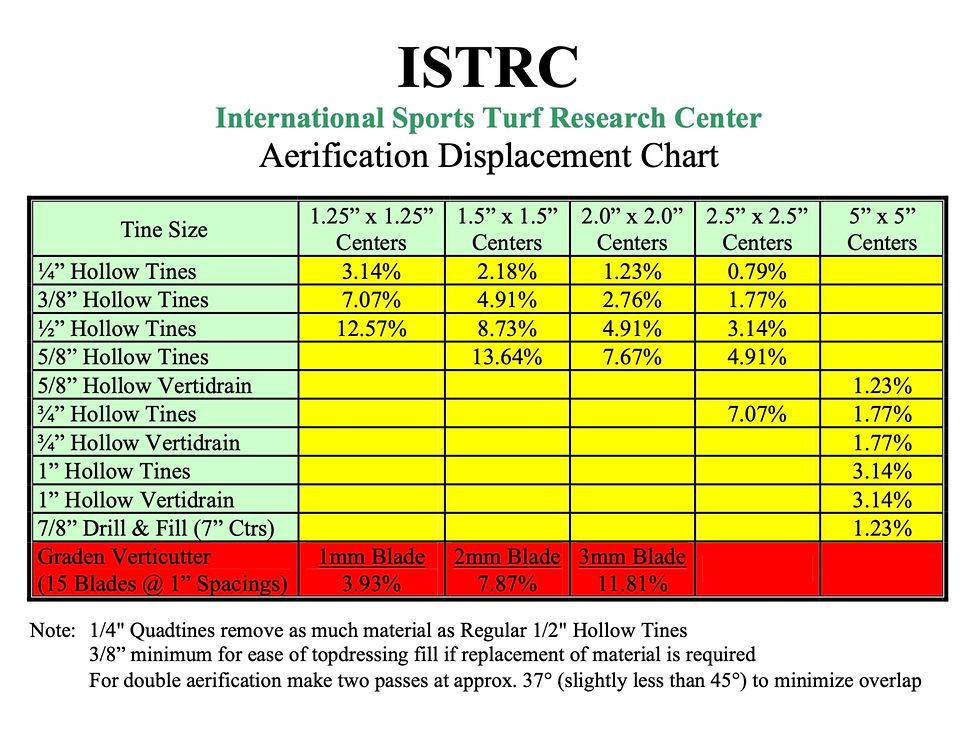

The plots were laid out on August 5, 2021. The first treatments occurred on that day. 10 gallons of water was applied to each plot. The rates, however, were 25 ppm, 125 ppm, and 250 ppm. Surface runoff was observed. On Day 2, August 6, Mr. Matt O’Dell, GCS, needle tined the plots at our request. The open holes permitted the solutions to penetrate the soil without loss to surface runoff. Another 10 gallons of each product at the previously stated rates was applied to each plot.

On Day 5, Monday August 9th, 6 gallons of water were applied to freshly needle tined plots by Mr. O’Dell with the 50, 250, & 500 ppm solutions. The process was repeated on Day 7 and Day 9. The chemical and physical samples were taken on Day 12, Monday August 16th.

On Day 1 chemistry samples and undisturbed ISTRC SYSTEMtm core samples were taken to document the chemical and physical conditions of Green #3 before treatment. The ISTRC undisturbed cores removed samples in 4-inch lifts. Three lifts, or “tiers”, were removed thereby testing the top 12 inches. Oxidized and reduction Fe & Mn was observed through the entire profile.

The chemistry samples were taken in the following 2-inch layers: 0 to 2 in. with the grass, 2 to 4 in., 6 to 8 in., and 12 to 14 in. The testing consisted of paste extract, weak acid, Mehlich 3 strong acid, and very strong acid digest.

On Day 12, the chemistry and ISTRC sampling was repeated but from the 500 ppm plots for both the pHix and Product B. Below is a spreadsheet of the chemistry for easy comparison. We also recorded weather statistics for the typical hot and humid St. Louis in the summer. Days 5, 6, & 7 were particularly stressful.

IV. TEST RESULTS

The table on Page 6 is a portion of the spreadsheet. In addition to the test results from the samples taken on August 5 & 16, it contains the historical testing data from September 26, 2020. The Very Strong Acid Digest (“VSA”) does not contain entries for September 26th because the testing was not requested.

In analyzing the data, we call your attention to Fe. The paste extract produces 0.8 ppm in the top 2 inches but the actual amount of Fe is 4492 ppm when isolated using the VSA. In the 2 to 4 in. strata, paste extract Fe is 1.33 ppm but the actual amount as isolated by the VSA dissolving the tight crystalline structures yields a result of 4513 ppm. The dark coloration and hardness in the top 4 to 5 inches are consistent with these results. There are similar increases for Ca; particularly, in the top 2 inches.

The weak acid and Mehlich III strong acid extracts did not adequately expose the true amount of Fe, Ca, and other elements. The amounts liberated by the paste extract, weak acid, and Mehlich 3 processes did not explain the extreme hardpan encountered with a penetrometer probe.

The York-Oppold Legacy Testing Package was developed over the last 5 years by Dr. David York and the undersigned. It was in response to traditional testing failing to adequately explain the hard conditions found below the surface of sand-based greens. We can surmise that similar chemistry issues exist in native soils but the presence of organic matter, silt, and clay have historically been cited as the reason for hard soil conditions rather than soil chemistry.

The use of acids have produced positive results in agricultural soils that are traditionally high – relative to sand-based greens – in organic matter, silt, and clay; however, it is easier to measure the impact of those products in a sand-based system built with a USGA-compliant sand because the impact of organic matter, silt, and clay are minimized. [NOTE: We recognize that organic matter is often high in the top 3 to 4 inches of a sand-based green; however, below the top 4 inches the test results contained in this report are in sand strata that have very little organic matter, silt, or clay.]

An interesting phenomenon is the increase in EC [mmhos/cm] as acid strength increases and depth increases. Product B had the higher EC near the surface but the pHix caught up by the 12-to-14-inch strata. The most likely explanation recognizes that the increase occurs because crystalline forms of the nutrient metals do not conduct electricity in the soil; but, the dissolution of those crystals – the liberation of the nutrients – places the nutrients into the soil solution where they are able to conduct electricity. Ideally, we want to prevent those solubilized elements from reverting to crystalline form.

The pictures below document the reduction Fe and the oxidized Fe in Green #3 on Day 1. The oxidized Fe appears at the base of the cup-cutter hole in the first photo.

Green #3 (1st Tier) - Untreated

The top 4 inches were needle tined for us by Mr. O’Dell for all but the first application of each product on their three test plots. The existence of holes at the surface, however, should not be interpreted to mean that the pHix or Product B did not react with the soil between the holes.

There is evidence in the physical properties, Table 1, that both products were producing chemical reactions. The infiltration rates were exactly the same for the untreated, Product B, and pHix samples. The changes were found in the air and water porosities. If you add them together to obtain total porosity, TP for the three samples is about the same. The differences are in the split between air and water pores.

There was also a substantial increase in the organic contents. The Walkley-Black Method measures carbon. It is highly unlikely that the increases from the untreated to the Product B and pHix samples was caused by root growth. The more likely explanation is that chemical reactions were mobilizing carbon.

You will also notice that carbon appears to be more mobile in the pHix due to its organic content percentages increasing and at a higher rate relative to Product B. [NOTE: The physical properties are very poor in each undisturbed core sample. The physical test results, nonetheless, indicate that positive changes are occurring in the treated plots.]

Green #13 (2nd Tier)

The 2nd tiers appear to have Fe splotches in their 4-to-5-inch layers. The test results indicate that Product B is having the greater impact on the physical properties. If you refer back to Table 1 and the bulk densities, you will observe that the pHix had the greater impact in lowering bulk density.

In the 2nd tier, the Product B was lower than the untreated sample while the pHix remained the same as the untreated sample. Nonetheless, percolation improved substantially with both products relative to the untreated sample. Total Porosity also improved in both Product B and pHix but the split between air and water pores differed.

This discussion is not esoteric. We have long speculated that high bulk densities, like the results in the 2nd tier samples, were not caused by an increase in compaction; rather, they reflected the weight of contaminants such as carbonates and other crystalline structures. It is in the pHix 1st tier, and in the Product B and pHix 3rd tiers, where we see a decline in bulk density that is significant.

There is a high probability that the acids are dissolving the carbonates and other crystals. We see the impact in the chemistry’s EC testing. Na, S, Ca, Mg, Fe, Al, Mn, and most other nutrients are metals that conduct electricity. The dissolved carbonates and crystals, however, do not disappear. The 2nd tier bulk densities may have remained high because the dissolved material in the top 4 inches migrated to the 4 to 8 inch depths.

Green #13 (3rd Tier)

The 3rd tier is where we see the most change. In 12 days, both products were able to produce measurable and significant improvements to the physical properties. Before the experiment began, we had speculated that the likelihood of measurable improvement was less than 20% probability. We opined that the 2nd tier had the higher probability of exhibiting changes caused by chemical reactions. We were wrong.

The changes in bulk density were substantial with both Product B and pHix; however, the pHix’s additional change of 0.05 g/cm3 relative to Product B’s bulk density is also significant. The changes in the percolation rates are equally impressive. Product B, however, produced the higher rate in addition to higher air porosity, and lower water porosity. It also had a percentage more in total porosity.

These changes occurred in a brief period of time. The next research project will endeavor to monitor one or more greens over a longer period of time. [NOTE: There is oxidized Fe in the untreated and the pHix time lapse photos. There had to be O2 available for the Fe to oxidize. It is possible that fresh air is entering the lower root zone through the tile and gravel drainage blanket.]

Above is the inch-by-inch analysis of the Textural & Sand Particle Size Distribution for Green #13’s (the Tare’s) 1st, 2nd & 3rd tiers, Product B 1st, 2nd & 3rd tiers and pHix 1st, 2nd & 3rd tiers. A complete inch-by-inch analysis for the tested greens is also attached to the end of the report.

The lower box contains the USGA specifications & ISTRC Guidelines - the upper set is the USGA specifications and the lower set highlighted in gray contains the expanded guidelines from ISTRC. The distribution of the sand is consistent throughout the profile. Topdressing has changed the top inch. The original root zone sand did not comply with the USGA recommendations.

The amount retained on the 80/100 sieves exceeded 20%. Silt/clay also exceeds the USGA’s recommendations. [NOTE: Relative to loam soils found in modified soil greens, athletic fields, and in agriculture, the silt and clay percentages are low.]

V. RECAPITULATION

The Product B was designed to dissolve carbonates and bicarbonates with urea buffered HCl. Other acid products may include sulfuric acid to lower water pH. The Curative in pHix is a buffered HCl although without urea (N).

The BC component of pHix is hydrogen peroxide based with acetic acid. The BC is designed to manage bacteria loads; break down bio-films, polysaccharides (aka “slime” per Dr. Bert McCarty) that are produced by bacteria. The “slime” contaminates air pores, slows water movement, while anoxic bacteria toxifies vegetation with H2S, and inhibits oxygen diffusion.

Hydrogen peroxide provides oxidation as well as O2 in the soil, continuous chemical aerification, which can also counter the amines produced by acidifying nitrates and other N compounds.

It is a broader spectrum product. Product B was effective in this research trial. The urea, however, caused an unwanted flush of growth. This is not the first time we have observed a flush of growth with a urea buffered acid product. It is the first time that we have observed a flush of growth in less than 12 days.

The pHix was also effective in this research trial. The changes in bulk density were significant. A longer trial is needed to monitor its ability to improve physical properties, soil sustainability, and plant health, as was initially intended.

The changes to the physical properties in only 12 days suggests that chemical remediation may be an important tool in rehabilitating sand-based golf greens. Green #3, for instance, was an excellent candidate for a complete rebuild.

A choice had been made to strip and re-grass the green, but the changes that occurred within a short time frame were substantial. Further testing is needed to determine whether a sand-based green can be returned to its post-construction condition. The prospects are enticing.

Sincerely,

Robert S. Oppold, V. P. – R&D International Sports Turf Research Center, Inc.

11372 Strang Line Rd.

Lenexa, KS 66215

CONTACT US FOR A DEALER NEARBY - DEALER INQUIRIES WELCOME

Your inquiry will be responded to immediately during business hours: (7:00am - 4pm MST)

Call or email us for more information about water and soil solutions: email: info@hctllc.com

Phone: (888) 788-5807

Comments